1) Short-circuit characteristics

The clamp can withstand a short-circuit with an effective current of 31’000 amps and a peak value of 78’500 amps in the first half-wave for 0.1 seconds.

Source: Berlin 2023 test setup with 50mm2 cable laid parallel to the rail.

The clamp can withstand a short-circuit of 16’000 amps for 1 whole second.

Source: Berlin 2023 test setup with 50mm2 cable laid parallel to the rail.

The clamp can withstand a short-circuit with an effective current of 79’400 amps and a peak value of 150’000 amps in the first half-wave for 0.1 seconds.

Source: Prévérenges 2010 test setup with 120mm2 cable laid vertically to the rail.

Video short-circuit test 79’400 Ampere

Short-circuit test 1995

Tested in laboratory “Oslo Energi Konsult AS” in Oslo.

Please click here to open the whole report.

2) Continuous currents

High continuous currents of up to 1,000 amperes for alternating current (AC) and 1,500 amperes for direct current (DC) can be born by one single clamp without any problem. The value for AC is lower because of the skin-effect. If necessary, more than one clamp could be used in parallel for even higher continuous currents over longer periods of time. However, this is certainly not necessary for peak currents.

Source: ABB test setup 2013.

The clamps heat up to less than 60°C with a continuous current of 200 amps and an ambient temperature of 20°C.

Source: Eurofins test setup 2023.

3) Contact resistance

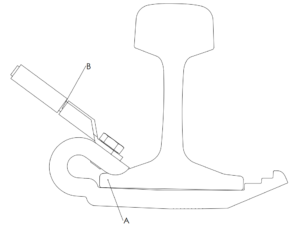

The clamp itself only generates a contact resistance between 100 and 150 micro-ohms (millionth of an ohm) from the cable lug (B) to the rail (A).

Source: Eurofins test setup 2023.

The contact resistance hardly changes during heating-up.

Source: ABB test setup 2013.

4) Signalling circuits

The clamp is also suitable for signalling circuits because it has a low resistance also when used only for small currents.

Source: ABB test setup 2017.

5) Atmospheric exposure

The clamp can withstand all weather conditions also in the long term: snow, rain, frost, heat, dust etc.

Source: Field experiences in 40 years from all type of customers all around the world.

6) Vibrations

When screws, bolts or nuts on KAGO clamps are tightened with the correct torque, they will not loosen even under severe rail vibrations. No additional locking element is necessary.

Source: FHNW Windisch test setup 2023 (frequencies of 5 to 2’000 Hertz).

7) No damage to the rail

KAGO clamps only scratch away the rust, leaving the rail undamaged.

Source: 3D InnoTec test setup 2023.

8) Repeated use

The clamp can be used more than 20 times if the mounting instructions are followed correctly.

9) Quick mounting

The clamp can be mounted within 5 seconds. Only a hammer and no other tools are necessary.

Please be aware that imitations of our product by other producers do not comply with these requirements.